product description

TYJX series variable frequency drive high-efficiency rare earth permanent magnet synchronous motor is a fully enclosed air-cooled motor designed by our company for the fan field. The efficiency index of this series of products reaches the GB30253-2013 permanent magnet synchronous motor energy efficiency limit value and the energy efficiency level is greater than Class 1 standard, reaching the advanced level of similar products. Due to the excellent magnetic properties of rare earth permanent magnet materials, it does not require additional energy after magnetization, and can establish a strong permanent magnetic field, which is used to replace the electric excitation of traditional motors field, the rare earth permanent magnet motor made is not only high in efficiency, but also simple in structure, reliable in operation, small in size and light in weight. response speed), and can be made into a special motor that can meet specific operating requirements. The combination of permanent magnet motor, electronic technology and microcomputer control technology can improve the performance of the motor and drive system to a new level, making the motor more intelligent. It is widely used in various fan fields.

Permanent magnet synchronous motor has the advantages of novel design, compact structure, high efficiency and high power factor, good starting torque performance, energy saving, low noise, small vibration, safe and reliable operation, high efficiency and energy saving, etc.

Features

high efficiency:The rated efficiency exceeds the national first-class energy efficiency standard and reaches the national standard IE5 energy efficiency standard.

High power factor:The permanent magnet motor rotor has no induction current excitation, the stator winding presents a resistive load, the motor power factor is above 0.95, and no reactive power compensation is required.

High return on electricity saving:Depending on the load conditions, instead of asynchronous motors, the comprehensive power saving rate is 15%-30%.

Small current:Compared with 3-phase asynchronous, the current is reduced by more than 20%, and no reactive power compensation is required. When the company plans the layout in the store, it can greatly reduce the investment in cables and transformers.

Low temperature rise:There is no copper loss in the rotor winding, no reactive current in the stator winding, and the temperature rise is lower than that of the asynchronous motor by more than 20k.

Good control performance:The permanent magnet synchronous motor is easy to control, has no speed slip, good dynamic response performance, precise speed control, and has greater advantages in occasions with high speed requirements.

Product parameters

motor model | power | Voltage | diameter | Rotating speed | factor | Insulation class | degree of protection |

TYJX-1500 | 1.1kW | S380V\/50Hz | 5.2M | 85 | 0.95 | f | IP55 |

TYJX-1500 | 1.1kW | S380V\/50Hz | 6.2M | 65 | 0.95 | f | IP55 |

TYJX-2200 | 1.5kW | S380V\/50Hz | 7.3M | 55 | 0.95 | f | IP55 |

TYJX-2200 | 1.5kW | S380V\/50Hz | 7.3M | 55 | 0.95 | f | IP55 |

TYJX-1100 | 0.75kW | D220V\/50Hz | 4M | 90 | 0.95 | f | IP55 |

TYJX-1100 | 0.75kW | D220V\/50Hz | 3.5M | 100 | 0.95 | f | IP55 |

TYJX-1100 | 0.75kW | D220V\/50Hz | 3M | 110 | 0.95 | f | IP55 |

TYJX-750 | 0.55kW | D220V\/50Hz | 2.5M | 120 | 0.95 | f | IP55 |

Principle of energy saving

1. The rotor of the permanent magnet synchronous motor uses high-performance rare earth permanent magnet materials to generate a fixed magnetic field (generated by permanent magnets and current), and the rotating magnetic field of the stator drags the rotor magnetic field (rotor) to rotate, so the rotational speed of the rotor must be equal to the synchronous speed, and no excitation current is required , excitation winding, to achieve high energy efficiency.

2. The asynchronous motor generates induced current in the rotor through the rotating magnetic field of the stator, and generates electromagnetic torque. The magnetic field is not directly generated in the rotor, so the rotor must be lower than the synchronous speed.

3. The power density of permanent magnet motors is about 30 percent higher than that of asynchronous motors of the same power. For motors of the same power, permanent magnet motors are 1-2 frame sizes smaller than asynchronous motors. Small size means small iron loss and mechanical loss Small.

4. The permanent magnet synchronous motor has higher efficiency than the asynchronous motor of the same power, and at the same time, the high-efficiency zone is wider. When the speed range of the permanent magnet synchronous motor is 25%-100% of the rated speed, the efficiency runs in the high-efficiency zone, while the speed range of the asynchronous motor , below 70 percent of the rated speed, the efficiency will drop sharply.

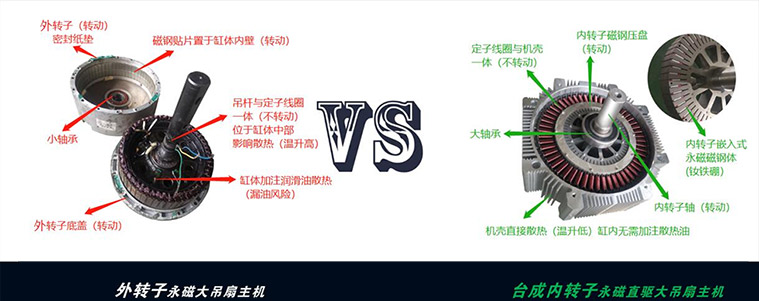

Ceiling fan motor stability comparison chart

Energy saving comparison chart